What is a smart factory? How is it impacting the manufacturing industry?

By Admin

The manufacturing industry has been one of the most critical cornerstones of global economic growth and the advancement of human lifestyle. As the industry continues to evolve and adapt to changing consumer needs, we have witnessed tremendous growth and innovation.

The innovation in end-products of the manufacturing chain firmly asks for innovation in the production and operational process, which has led the manufacturing industry to leverage modern technology to implement the smart factory concept.

Before jumping into the impact of smart factories on the manufacturing industry, let’s briefly understand what a smart factory is.

What is a smart factory?

At the core, a smart factory is a wholly digitised manufacturing factory/facility. If you take a regular factory and digitise all its operations and processes, you have your smart factory ready. However, it is easier said than done.

Digital manufacturing methods, IoT devices, centralised custom software, shared historical data, and many other items must be implemented to digitise a factory.

Smart factories leveraging the best possible amalgamation between the digital and physical worlds are set to revolutionise the manufacturing industry. The investment of time, money, and resources will pay off heavily to the manufacturing business owners as smart factories benefit operators, managers, and executives in improving manufacturing operations, informed decision-making, and more.

Let us take a deeper look at the elements of smart factories and the technology leveraged for them.

Key technological elements of a smart factory

-

Cloud-based Custom Software for Manufacturing

The first and foremost need to digitise any factory is to have customised manufacturing software tailored to your business-specific requirements. A cloud-based custom software is a hub for connecting and managing all the digitisation happening across the factory.

-

Robotics & IoT

Manufacturing factories in this decade have already implemented basic-level of robotics at a large scale. Many production operations are now automated with the implementation of robots with human operators; however, robotics combined with IoT is a step towards advanced manufacturing. Intelligent robots, with the help of IoT, will be able to handle smart materials, adaptive and complex operations without constant manual supervision.

-

Big Data Analytics

Accessibility and management of organisational data are crucial to a smart factory's successful and efficient operation. Custom software with big data analytics capabilities can give you access to view all the administrative data from a single dashboard at any given time. This also enables you to make more informed and data-driven decision making.

-

Virtual and Augmented Reality

Both virtual and augmented reality can be miraculously game-changing in the planning phase of manufacturing. VR & AR lets you visualise and experience the product in the real world via a special type of glasses or a smartphone before even starting the manufacturing process, saving you a lot of time and resources in prototyping.

-

Additive Manufacturing/3D Printing

Additive manufacturing or 3D printing lets you quickly produce prototypes for the main product to be manufactured. It saves a massive amount of time and money for testing and prototyping the products.

Above mentioned are the basic essential technological elements to turn a factory into a smart factory. Going further, manufacturing facilities can also leverage digital twins, cyber security and other advanced technology as well. Possibilities are endless!

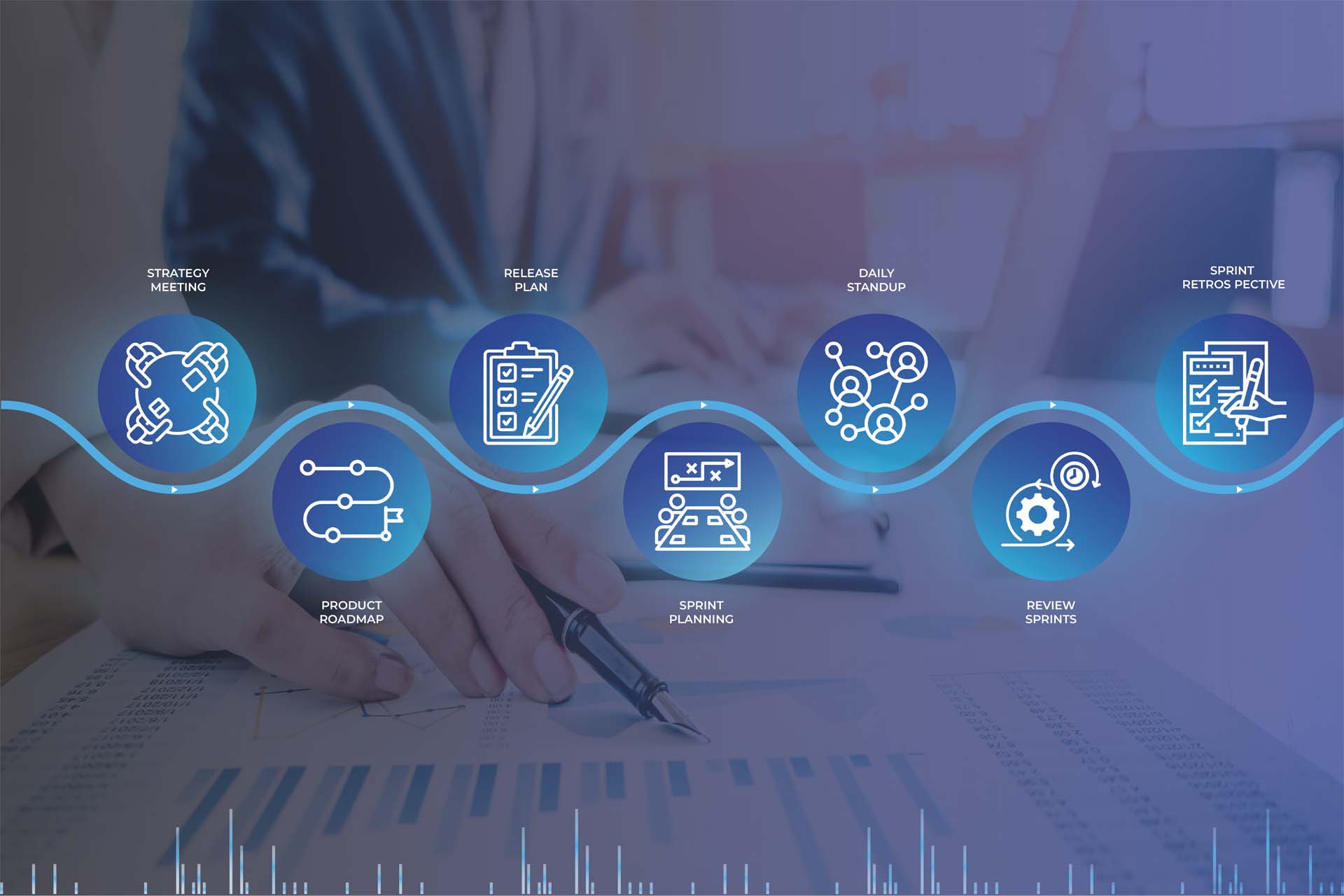

Envisioning a sustainable future for manufacturing businesses

After understanding the concept of smart factories and what goes behind them, the question arises of why it is so impactful to the manufacturing industry and how it will benefit the complete manufacturing ecosystem. Well, let us give you a quick glimpse into the impact of smart factories on the manufacturing industry.

Agility to keep up with changing industry trends:

We are living in a rapidly changing world. The trend for today might not exist next week. The growing demand for a customised and trendy products causes chaos for manufacturers. Smart factories with the implementation of additive manufacturing and robotic process automation (RPA) will handle this challenge gracefully.

Reducing waste of raw materials and cost overheads:

A failed manufacturing lot costs thousands, if not millions, to any medium or large sized manufacturers. Experiencing products in virtual reality before even purchasing raw materials can save you from this trouble. Cost overheads can vastly be reduced by automating repetitive operations by robots and focusing human labour on more critical parts of the business.

More informed decision-making to make the business thrive:

Larger datasets give more accurate predictions for the future. Having historical organisational data accessible in a single dashboard can help business owners to form their strategic business plans for the future. Data-driven decision-making can highly influence the business for the better.

These are some of the benefits that smart factories offer to manufacturing businesses. If you want to know more about how technology can revolutionise your manufacturing business for the better, feel free to contact us. Our experts will be happy to help you!

Insights

Insights into

our World

A view of the ever-evolving digital world through our screens